Further removal of material from the casting to achieve its desired final dimensions and appearance

DELIVERY

PACKING

OUTGOING INSPECTION

EQUIPMENT

CMM (Brown & Sharpe)

Portable FaroArm and ROMER Arm

3D Portable Scanner; Creaform Handyprobe and Metrascan

Surface Roughness Tester

Inspection Software: PC-DMIS CAD++, Discus FAI, PolyWorks

COATING

FINISHING / ASSEMBLY

MACHINING

Further removal of material from the casting to achieve its desired final dimensions and appearance

EQUIPMENT

CNC Vertical and Horizontal Lathe

CNC Vertical and Horizontal Milling

CNC Slotting

Surface Grinders

Conventional Machines

NONDESTRUCTIVE TESTING

Supplementary tests to evaluate the properties of the castings

EQUIPMENT

Ultrasonic Flaw Detector

Dye Penetrant Inspection System

DEGATING & FETTLING

Removal of gates, runner, and riser system | Cleaning of fins, rough edges, and other extra material

EQUIPMENT

Bench Grinders

Power Grinding Wheels

Swing Grinder

DESANDING

Removal of remaining adhering sand and coating from the casting surface

EQUIPMENT

Hanger-type Blast Machine

Batch Type Tumblast Machines (5 units)

SHAKEOUT

Taking out castings from the mold after cooling

SAND QUALITY CONTROL

Molding sand quality inspection using sand testing equipment and methods based on AFS standards.

EQUIPMENT

Laboratory Sand Mixer

Moisture Analyzer

Universal Sand Strength Testing Machine

Rotary Sieve Shaker

Friability Tester

Permeability Tester

Clay Washer

CORE MAKING

Producing cores by hot or cold box blowing or no-bake ramming of sand into a core box

EQUIPMENT

Automatic Shell Core Machine (5 Units)

Manual Shell Core Machine (3 Units)

Core Drilling Machine

MOLDING

EQUIPMENT

(4) Horizontal HP Molding Machines

(1) Vertical HP Molding Machine

(26) Jolt/Squeeze Machines

Furan No-Bake Molding

CO2 Cold Box Molding

TOOLING FABRICATION

Making of mold pattern and core box | Fabrication of fixtures, jigs, and gauges

EQUIPMENT

Large-format 3D Printer (Print Volume of 1200 x 600 x 600 mm

Traditional wood cutting machines

Machining centers

SIMULATION

Devising and visualizing an optimum casting method by software simulation of the casting process from filling to solidification

EQUIPMENT

NovaCast Systems

NovaFlow&Solid

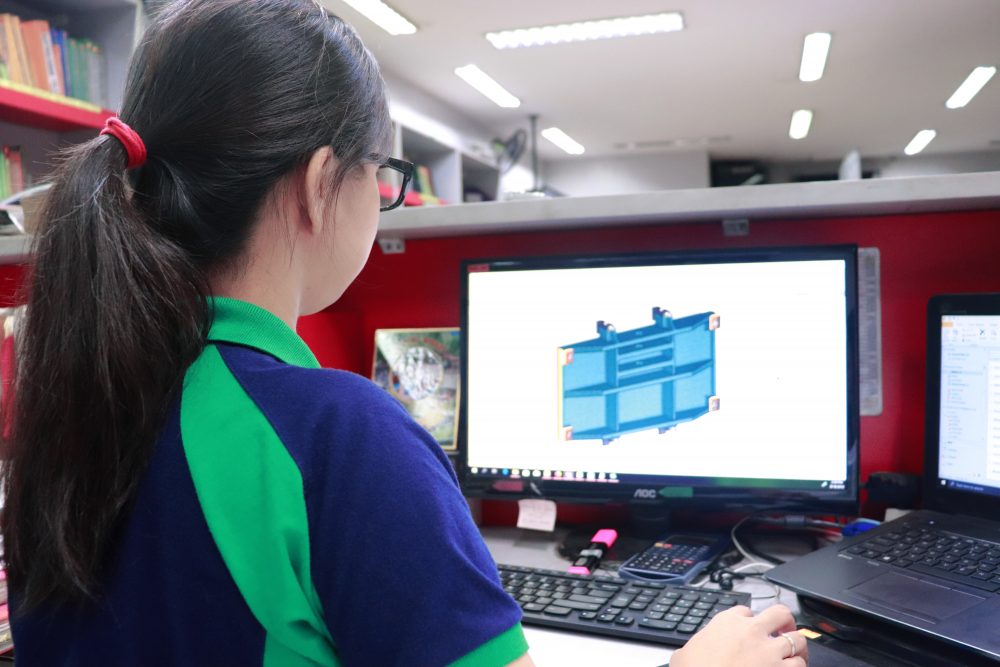

CAD/CAM

Designing a cast product | Making NC data for controlling manufacturing processes

EQUIPMENT

SolidWorks / SolidCAM Systems

PLANNING

Defining and scheduling the operations on the shop floor

EQUIPMENT

ERP System

HEAT TREATMENT/ SURFACE TREATMENT

Optimizing metal properties by heat treating or surface modifications

EQUIPMENT

Heat Treatment Furnace

Quenching Pool

Muffle Furnaces

DIMENSIONAL INSPECTION

COMING SOON!

TOOLING INSPECTION

Quality control inspection of tools prior to use on the shop floor

EQUIPMENT

CMM

3D Scanner

Discus FAI Software

PC-DMIS CAD++

PolyWorks

MATERIAL TESTING

Testing and analysis of metal to check for its physical, chemical, and mechanical properties

EQUIPMENT

OES Spectrometer (Chemical Analysis)

CE Meter (Thermal Analysis)

Universal Testing Machine (Mechanical Testing)

Image Analysis Software (Metallographic Analysis)

Metallurgical Microscopes (Metallographic Analysis)

Rockwell, Brinell, and Leeb Hardness Testers (Hardness Testing)

MELTING & POURING

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod temp nostrud exercitation o quisquam est, qui dolorem ipsum quia dolor sit amet, consectetur

EQUIPMENT

4-MT/Hr Cupola Furnaces (2 Units)

500-kg Induction Furnaces

Crucible Furnaces

2-MT/Hr Cupola Furnace

QUALITY CONTROL & ASSURANCE

At SFMC, we combine our quality guidelines and procedures with those of the customers to produce the products that meet and exceed their expectations. We always boast of our QC equipment and tools that always keep up with the advancements in the global standards of quality.

MACHINE SHOP

Our machine shop is a medium-sized facility with both manual and CNC machines that allow us to do single parts as well as large production runs.

FOUNDRY SHOP

Supercast's foundry shop is capable of making a wide range of parts from basic shapes and sizes to complex profiles and customized specifications with its utilization of a variety of molding machines and melting furnaces.